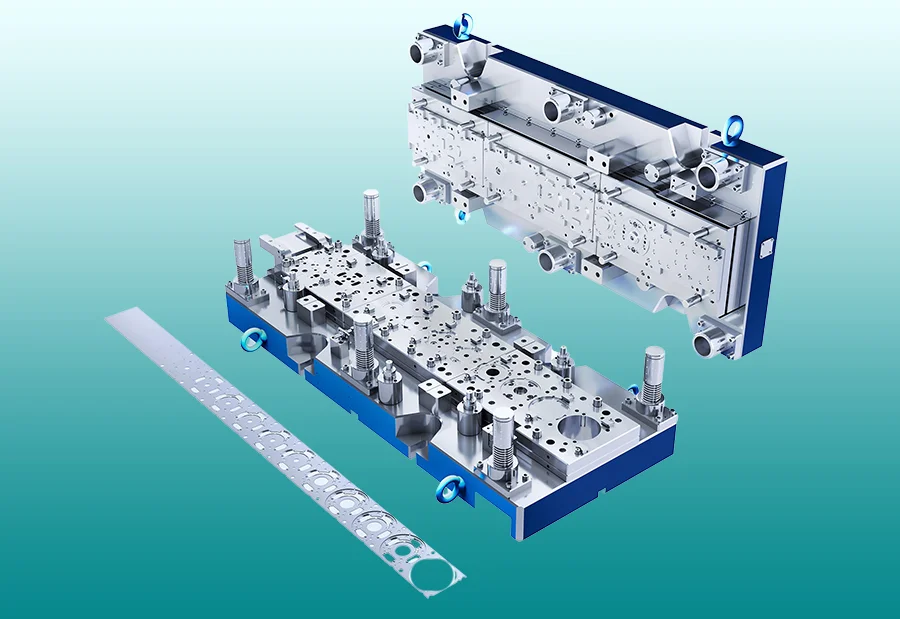

Progressive die components are the backbone of productivity in high-volume metal stamping operations. Yet even the most accurate tooling systems suffer wear and loss of performance over time, especially in areas of high stress. For progressive die manufacturers, wear-prone areas and strengthening them is not just a matter of durability—it’s a matter of dimensional accuracy, minimizing downtime, and avoiding expensive breakdowns.

This blog examines the most common high-wear zones in progressive die components, the issues they cause, and engineering strategies to address and reinforce them for long-term reliability.

Identifying High-Wear Zones: Where Problems Begin

The first step toward extending progressive die component life is identifying the components most vulnerable to wear. These include:

1. Cutting Punches and Die Openings

- Subject to repeated impact and shearing

- Prone to burr formation, edge chipping, and galling

- Misalignment or inadequate clearance raises the wear rate

2. Stripper Plates and Guide Rails

- Intense surface contact results in frictional wear

- Galling, scratches and material pickup are typical

- Poor lubrication speeds damage

3. Forming and Bending Radii

- Subject to high stress from metal deformation

- Can develop fatigue cracks or micro-spalling with age

4. Pilot Pins and Feed Mechanisms

- Essential for exact strip alignment

- Exposed to wear that induces feed error and dimensional drift

Typical Problems in These Zones

Based on both industry reports and field experience, progressive die wear usually results in:

- Inaccurate dimensions in stamped components

- Slug pulling, which impacts downstream processes

- Sticking and jamming in feed lines

- Micro-fractures or cracking within tool steel

- High-frequency tool replacement and stoppages

- Troubleshooting strategies for high-wear areas

Troubleshooting Techniques for High-Wear Zones

The following are real-world techniques to troubleshoot progressive die components:

Visual & Microscopic Inspection

Employ magnification to identify hairline cracks or damaged punch corners.

Dimensional Auditing

Take regular measurements of important part characteristics to detect drift due to tool wear.

Die Tryouts and Simulations

Make controlled tests to separate misfeeds, misalignment, or galling.

Root Cause Analysis

When burrs or cracks consistently appear at the same location, review tool geometry, clearances, or material properties.

Monitoring System Integration

Sensors on progressive dies can monitor abnormal forces, temperatures, or stroke irregularities associated with wear zones.

Engineering Solutions to Strengthen Progressive Die Components

After weak areas are identified, reinforcement measures can be implemented to improve long-term performance.

1. Material Choice and Heat Treating

- Use hardened tool steels, such as D2 or M2, or carbide for punches and inserts.

- Perform localized heat treatment on wear areas to achieve a balance of hardness and toughness.

2. Coatings and Surface Treatments

- PVD Coatings (TiN, TiAlN): Minimize wear due to high-speed shearing

- DLC Coatings: Ideal for high-contact, low-lubrication conditions

- Ion Nitriding: Hardens surface without weakening core strength

3. Modular Design and Replaceable Inserts

- Design replaceable carbide inserts for high-wear surfaces (such as die openings)

- Reduces time for tool replacement or repair downtime

4. Advanced Lubrication Systems

- Incorporate centralized micro-lubrication systems to maintain a consistent oil film.

- Eliminates dry hits and lowers friction on strips and guides

5. Clearance Optimization

- Set and maintain proper punch-to-die clearance depending on material type and thickness.

- Tight tolerances without adequate clearance, speed wear, and part defects

Continuous Improvement Practices

Top progressive die makers today combine engineering and data:

- Apply CAD/CAM-based simulation to predict wear hotspots upfront in the design process.

- Utilize predictive maintenance in conjunction with production data and wear cycle models.

- Encourage cross-functional cooperation between tool designers, press operators, and maintenance personnel for quick problem-solving

Final Thoughts

Progressive die components are advanced systems, but regardless of their design quality, they require proactive maintenance and intelligent reinforcement to maintain sustained performance. Through high-wear area identification, utilization of the correct materials and coatings, and a diagnostics-driven maintenance strategy, manufacturers can achieve longer die life, minimize downtime, and improve stamping quality.

Want to increase the longevity and reliability of your progressive die components? Collaborate with progressive die manufacturers who integrate precision engineering with contemporary troubleshooting and diagnostics.

At CMD Precision Products Pvt. Ltd., we are experts in creating high-performance dies supported by predictive maintenance techniques and material science knowledge. We are here to assist you in strengthening what is most important—productivity, part quality, and tooling reliability.